Rotomolding technology

CZ PLAST has been since very beginning focused on just one plastic processing technology – rotomolding.

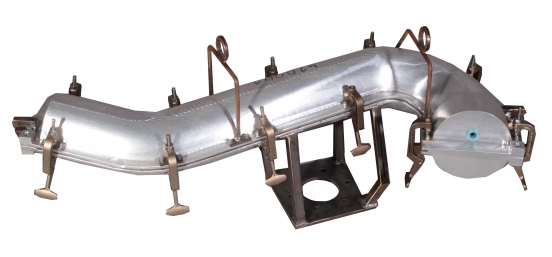

We meet daily products of this technology in many branches – industry, agriculture, construction, army, leisure time activities, etc. Always a hollow part is made, which can be modified to single-skin “open-ones” during finishing operations. Among the main advantages of this technology for sure belong extraordinary variety of sizes, shapes, colours and potential use of the final products.

Advantages of rotomolding technology

CZ PLAST has years of experience in custom molding – top-tech technological equipment together with skilled team of designers and technicians. Thus, we can customise the production to your needs.

The advantages of rotomolding technology are as follows:

- Advantageous also for small series of product

- Variability of sizes and shapes of products

- Variability of products’ wall thickness

- Definition of complex shapes and details directly in production (e.g. threads, necks in plastic, etc.)

- Using of inserts for setting of complex and more exact details (flanges for level indicators, fixing points, etc.

Production description

Rotomolding is up-to-date technology widely used round the world.

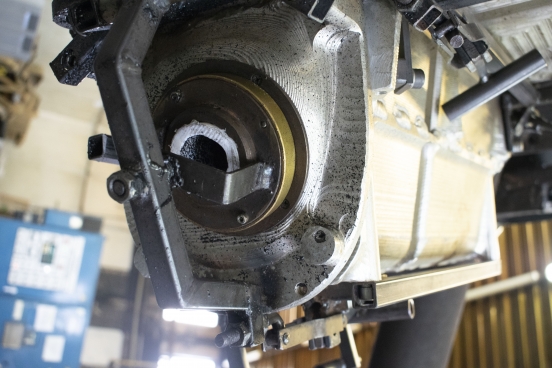

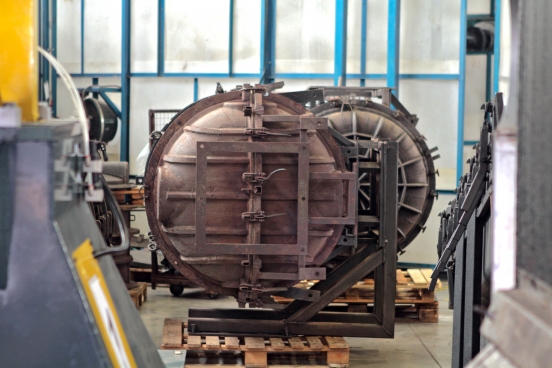

Rotomolding is the process of producing hollow parts by adding plastic powder to a shell-like mold and rotating the mold about two axes while heating it and the powder. During rotation, the powder fuses against the inner mold surface into a bubble-free liquid layer. The polymer is then cooled to near room temperature, and the resulting hollow part is removed.

We do process this way polyethylene, cross-linked polyethylene, polypropylene and polyamides. We can manufacture double- and triple-layer products.